2 Jaw Long Stroke Parallel Gripper GX Series Tecnair

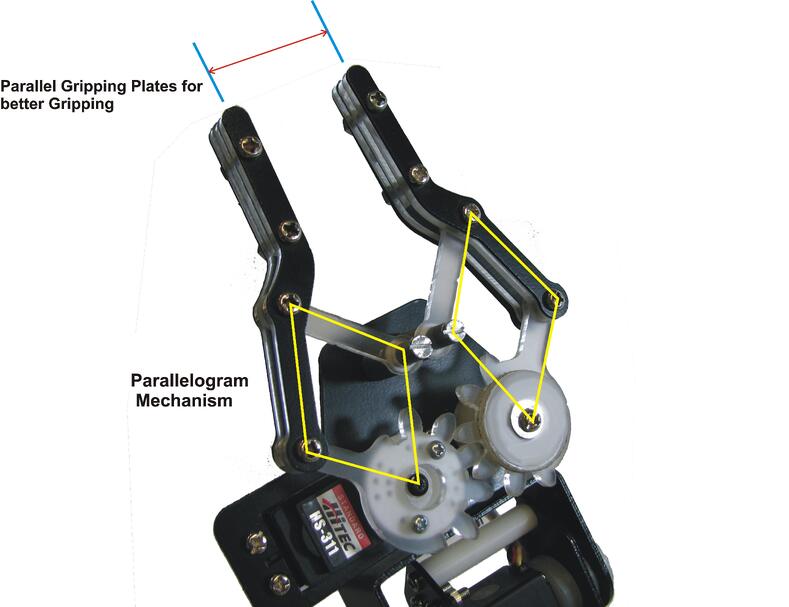

A gripper design is adapted to offer grasping and scooping capabilities to a parallel robot. This enables the parallel robot to manipulate not only large objects, but also thin objects lying on flat surfaces. Moreover, this gripper is driven directly by the redundant degrees of freedom of the parallel robot to which it is integrated.

Parallel gripper PGR sturdy design Mader Shop pneumatics & compressed air technology

The difference between robotic grippers with parallel, three-finger, and angled designs | Machine Design 3D Printing & CAD AUTOMATION & IIOT Identifying the best gripper for the application.

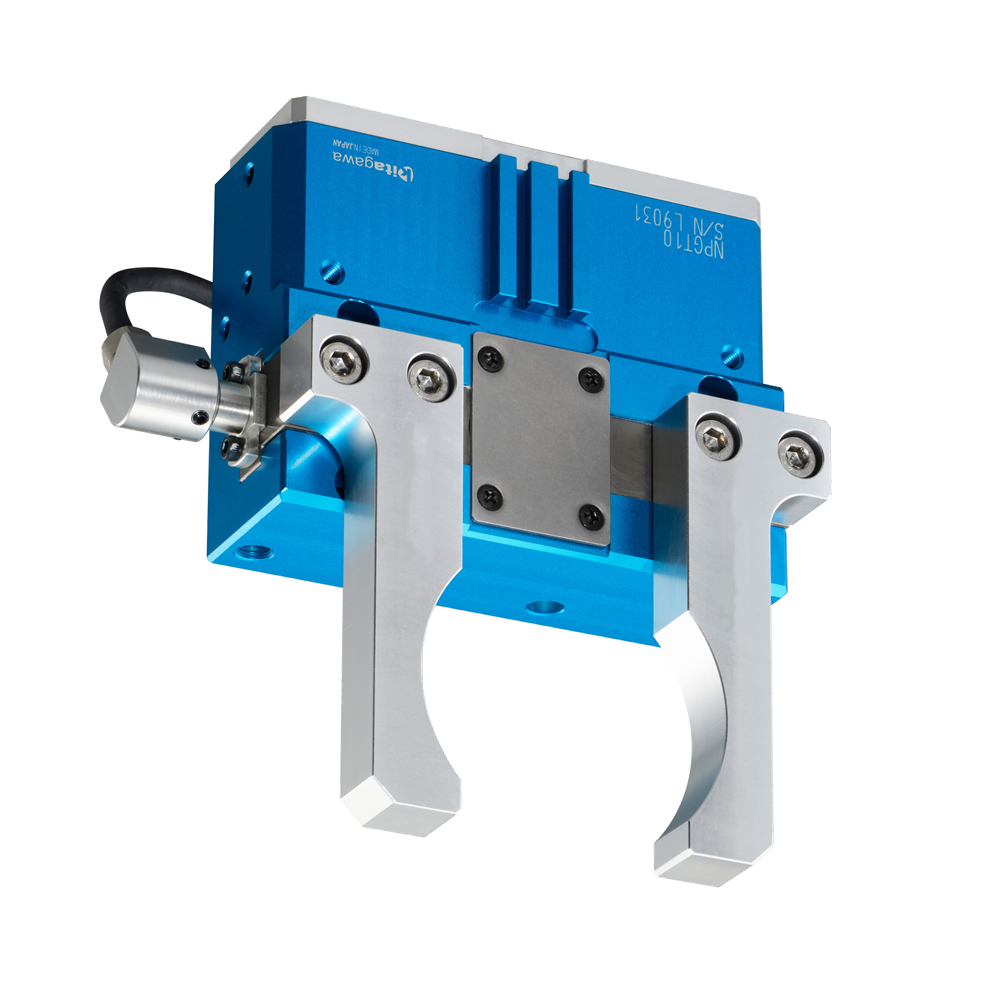

2jaw parallel gripper NPGT_S series by Kitagawa News

Parallel gripper From micro assembly to heavy-load handling Our standard parallel grippers include small parts, universal, long-stroke, and sealed grippers for safe and precise handling of workpieces.

Parallel Gripper P5GW Series (3 jaw centering) ParkerCA

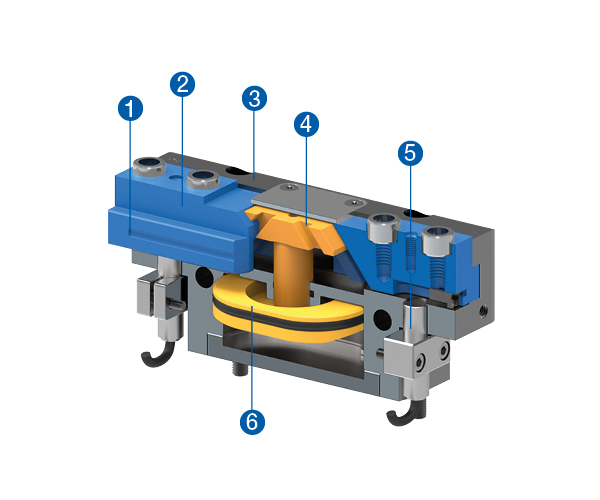

A parallel gripper that can grasp an object notjust between the fingers, using the linear trajectory, but also in front of the fingers, using the curved trajectory, is proposed. With an aim to make it dust-and-waterproof, the link structure is designed to combine two mechanisms consisting of only revolute pairs, called the Chebyshev's lambda mechanism and double parallel link. The former.

2 Jaw Guided Parallel Gripper GU Series Tecnair

Abstract—Parallel-jaw robot grippers can grasp almost any object and are ubiquitous in industry. Although the shape, texture, and compliance of gripper jaw surfaces affect grasp robustness, almost all commercially available grippers provide a pair of rectangular, planar, rigid jaw surfaces.

Parallel grippers Röhm clamping devices drill chucks, lathe chucks, HSK tools

A new parallel-type gripper mechanism is proposed in this work. This device has a parallelogramic platform that can be flexibly folded. Therefore, this mechanism not only can be used to grasp an object having irregular shape or large volume, but also can be utilized as a micro-positioning device after grasping objects.

Universal 2Finger Gripper JGP New Parallel Gripper from SCHUNK

mechanism to convert parallel gripping motion to continuous rotating motion. (a-1,2) The CAD models of the design. (b-1) A prototype. (b-2,3) The prototype held by a parallel gripper. Note: Only the front end is visible. The back end is the same as the front end except that the rotating direction is reversed.

Active Parallel Gripper Active8 Robots

In this paper, an idea of modular design is proposed to devise a compliant microgripper with two degree-of-freedom (2-DOF) along with parallel translational motion of the gripper arms.

Weiss Robotics GRIPKITE1 ServoElectric Parallel Gripper Thinkbot Solutions LLC

For example, when considering industrial grippers, one of the simplest designs is the parallel motion two-jaw gripper, commonly used to lift objects [12,13,14,15]. Several other design types include the O-ring gripper [ 16 ], and the needle gripper [ 17 ].

Parallel robot gripper Diekmann Engineering

A new parallel-type gripper mechanism is proposed that has a parallelogramic platform that can be flexibly folded and not only can be used to grasp an object having irregular shape or large volume, but also can be utilized as a micro-positioning device after grasping objects. View on SAGE researchgate.net Save to Library Create Alert Cite

Parallel gripper from ASUTEC for precise handling

This article develops a mechanical screwing tool and its manipulation policies for two-finger parallel robotic grippers. The tool is based on a combined scissor-like element (SLE) and double-ratchet mechanism that converts the gripping motion of two-finger parallel grippers into a continuous rotation to realize tasks like fastening screws. The tool is entirely mechanical. There is no need for.

Rigged long parallel gripper model TurboSquid 1310939

A compliant gripper with nearly parallel gripping motion is developed by a topology synthesis and a dimensional synthesis approach. The topology synthesis process can generate linkage-type compliant mechanisms. Suitable boundary conditions of the topology synthesis process are selected to achieve the desired functions of the device.

How to Choose a Parallel Gripper for My Robot?

Article 12 February 2019 Design and analysis of the gripper mechanism based on generalized parallel mechanisms with configurable moving platform Article 16 November 2021 Conceptual Design and Kinematic Analysis of a Novel Parallel Manipulator with an Articulated Gripping Platform Chapter © 2016 Abbreviations X F :

How Does a Parallel Robot Gripper Work?

A compliant gripper with nearly parallel gripping motion is developed by a topology synthesis and a dimensional synthesis approach to meet various design goals, and a nondominated multi-objective genetic algorithm is selected for the optimal design process. A compliant gripper with nearly parallel gripping motion is developed by a topology synthesis and a dimensional synthesis approach.

2131 SMC Low Profile Parallel Gripper

The etymology of the phrase, parallel gripper, relates to the fact that the gripper's fingers will remain in perfect parallelism throughout all the gripper's opening and closing movements. A parallel gripper is generally used for pick and place operations where parts have a predictable geometry.

Buy Parallel gripper HGPM online Festo USA

mechanical. There are no additional requirements for power cables or air tubes. There is also no special requirements for robotic end-e ectors. The tool could be used by any robots with 2-finger parallel grippers. The features of the design are: 1) The tool is mechanical and is only manipulated and actuated by robotic grippers.